energy saving low ash fish feed production line

-

Fish Feed Formulation Ingredients: Method, Calculation

Fish feed formulation is the process of combining different ingredients to create a balanced diet that meets the nutritional requirements of fish. The goal is to provide fish with the nutrients they need for growth, reproduction, and health at an economical cost.

Get Price -

Floating Fish Feed Production Line|Automatic Pellet

180-200 KG/H Dry Type Single Screw Fish Feed Production Plant; 1-1.2 T/H Wet Type Fish Feed Production Line; Twin Screw Fish Feed Production Line; Pet Food Production Line; Ring Die Sinking Hard (Aquarium & Farmed) Fish Feed Pellets Production Plant; Fish Feed Extruders. Dry Type Single Screw Extruder; Wet Type Single Screw Extruder

Get Price -

Production and characterization of fish protein hydrolysate

Oct 1, 2022 · The purpose of this research was to investigate whether both acid and enzymatic hydrolysis could be used to produce fish protein hydrolysate from low-value fish using papain and proteinase K enzymes, which can be used as a supplement in conventional human and aquaculture feed to enhance nutrition.

Get Price -

Fish Feed Production Systems - Food and Agriculture Organization

•1. Nutritional content of the feed is guaranteed (you can exactly know the nutritional level of the feed), •2. there is no change according to the season of the year, •3. You can buy it whenever you want from fish feed plants, •4. It is easy to store the feed.

Get Price -

.jpg)

Variations in Methods for Quantification of Crude Ash in

Aug 19, 2022 · Methods. The “control” method was based on a simple ignition time of 3 h at 550°C. The variations are briefly described: increasing ashing time to 6 h; increasing temperature to 600°C; and using two 3 h ignition cycles at 550°C with ashing aids inclusion between them: fresh air supply, fresh air supply plus distilled water, and fresh air supply plus hydrogen peroxide.

Get Price -

.jpg)

The relationship of feed intake, growth, nutrient retention

May 30, 2022 · Feed efficient fish ate smaller meals while maintaining higher growth rates. Protein, lipid and energy retention were increased in feed efficient fish. Whole body lipid composition cannot be used as a proxy for feed efficiency.

Get Price -

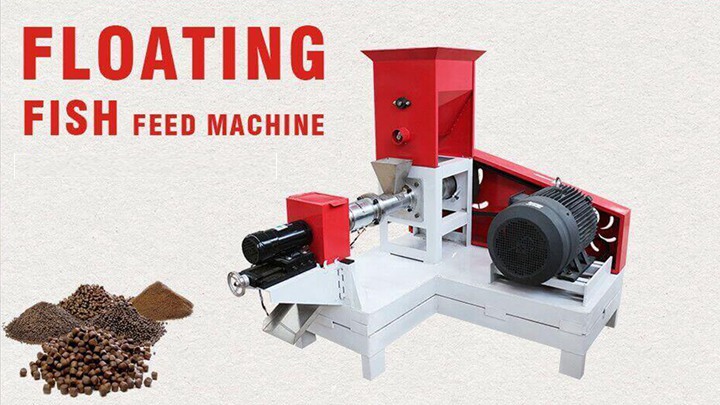

Energy Saving with Ce, SGS Certificate Pet Food Processing

Energy Saving with Ce, SGS Certificate Pet Food Processing Line /Floating Fish Feed Machine Price, Find Details and Price about Floating Fish Feed Machine Price Pet Food Making Machine from Energy Saving with Ce, SGS Certificate Pet Food Processing Line /Floating Fish Feed Machine Price - Henan Hanson Industry Co., Ltd.

Get Price -

Ghana exploits local feed resources to increase fish production

Dec 5, 2023 · The technology has low water usage, energy efficient and easy to harvest fish. Vice-President Alhaji Dr. Bawumia gave an address at the awards ceremony on behalf of President Nana Addo Dankwa Akufo-Addo, outlined the government’s programmes and policies aimed at ensuring food security in the country.

Get Price -

.jpg)

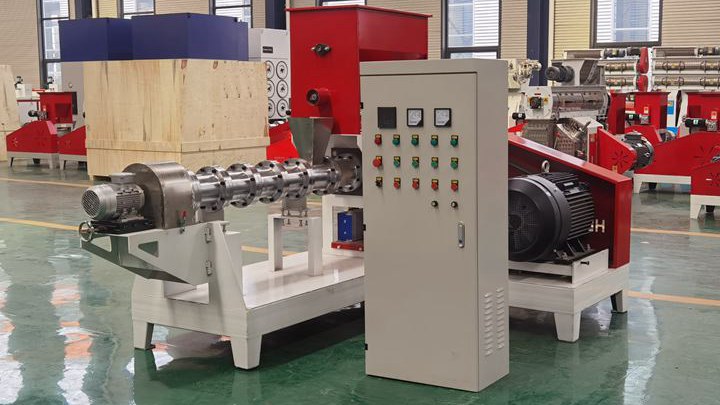

Qualified Fish Feed Extruders and Feed Production Line by

Anyway, how to reduce the cost of feed includes 3 points, first is to complete the steps in feed production to achieve the ultimate goal, there is no waste; second is to ensure the production effectiveness, no additional loss; third is to ensure the effectiveness of production machinery, factory should have a variety of detailed production data.

Get Price -

Fish Feed Production System - Eco AquaCulture Thailand

Nutritionally-balanced, custom-formulated, low-impact fish feed production facility at our farm in Phuket Thailand. We established early in our company’s life the need for high quality, nutritional feeds for our fish.

Get Price -

.jpg)

From straw to salmon: a technical design and energy balance

Sep 20, 2023 · Including the energy demand for feed production and fish farming, salmon fed with yeast oil-based feed would accordingly have a PED fossil of 28.5 GJ per tonne of fish, compared with 28.8 GJ for salmon fed the reference mix.

Get Price -

.jpg)

Energy efficiency of aquaculture - Responsible Seafood Advocate

Sep 1, 2010 · Feed production is commonly the major energy-consuming process in finfish and crustacean production systems. Processing accounts for roughly an additional 10 percent of the energy use for most seafood products, while consumption contributes about 20 to 30 percent.

Get Price -

What Are The Raw Materials For Feed Mill Production?

Description: A staple in feed mills, corn provides a high-energy carbohydrate source that is fundamental in many feed formulations. Nutritional Value : High in energy, low in protein, and contains essential fatty acids.

Get Price -

Tilapia Feed Ingredients : Best Tilapia Fish Feed Formulation

introduction of tilapia fish. Tilapia is a tropical fish, belonging to the order Perciformes, family Lippiaceae, with fast growth, mixed food, few diseases, strong adaptability and other characteristics. tilapia is an important agricultural aquaculture project, and it has high farming value and significance. the fish of tilapia has a wide range of eating habits.

Get Price -

Fish Feed Production Line - Henan Fuerstar Intelligent

Fish feed production line is specially designed for fish farmers, feed mills and high-grade shrimp feed manufacturers with low cost and simple operation. Fish Feed Production Line Features: Fish feed production line process: raw material preparation → mixing → conveying → extrusion puffing → conveying → drying → oil spraying →

Get Price